We hear the footsteps of springs now.

Japanese plum blossoms begin blooming in the small corner of outside of our building.

Plum blossoms are one of the representative flowers which are full bloom in the cold season at the end of winter.

Language of these beautiful flowers are "Keep your promise"," fidelity", "Beauty and longevity".

Plum blossoms ware so popular among the aristocrats in Japan.

Seisho Nagon who is very famous female writer of the Makura no Soshi (The Pillow book) in Heian era (11th century) loved plum blossoms so much especially red plum blossoms.

She wrote about the red plum blossoms as follows; Konohana ha Koki mo Usuki mo Kobai.

It means that; The most beautiful flowers among tree flowers are the red plum blossoms wheather the color of flowers is light or dark.

Plum blossoms blooming in the still cold season is also the symbol of beautiful women of Japan who live strongly even under a lot of difficulty.

Well, today is the last column about the serie of Nanbu tekki,

We will introduce how to manufacture this fine and beautiful ironware.

As you know, this Nanbu tekki is "iron casting product".

Iron casting means pouring the melted metal into the mold of some shape. Modern iron casting is by the process of machines but Nanbu tekki is manufactured by the hands of craft person with the sophisticated technique based on the traditional way.

The process of manufacturing Nanbu tekki.

1, Design the shape

Draw the design of picture and decide the shape of product.

2, Cross-section of design

Cut the metal plate of the shape of cross-section of product design.![]()

3, Make a mold

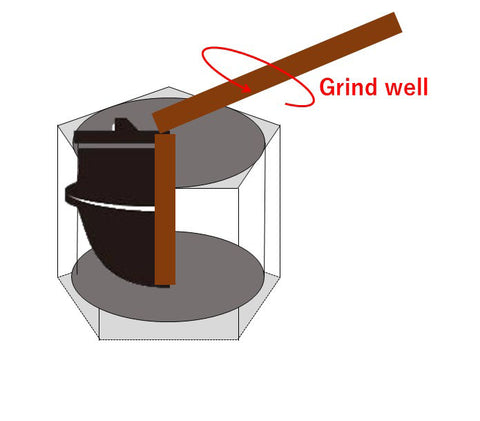

Mix the sand and clay by hand, then set the metal plate of "process 2" to grind well.

The shape becomes like the design already decided like "process 1."

4, Emboss the pattern interior of the mold before dry up.

5, Bake above mold (process 3) over the charcoal with the temperature 800℃

6, Shape the hollow part of product with sand.

7, Put the hollow part in the mold and pour the melted iron in.

8, Bake the whole mold over the charcoal with the temperature 900℃.

9,Polish up the surface of product.

10, Heat the product with the temperature 250℃, then apply the cashew paint.

Regarding the process of the Nanbu tekki we deal, please see the manufacturing process from following movie.

Please enjoy the crossing world of traditional way and modern technology.

https://youtu.be/axGveIQATJw

Thank you for reading this the end!

If you are interested in more, please browse our products page.

https://store.kyotohandicraftcenter.com/collections/ironware